-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Often acrylic and Plexiglas are often mistaken for the same product because they are both sheet plastics. Plexiglas is basically a trade or brand name for acrylic and is made from acrylic, but there are many significant differences in how acrylic is manufactured.

1. Extrusion/extrusion method

2. Cellular tube type

The extrusion method of manufacturing acrylic is less expensive, but has two problems. One is that it tends to be much softer than cell-cast acrylic, which causes it to scratch more easily. Second, the surface of the extruded acrylic may have impurities. While it may appear to be a deal breaker, this type of acrylic can be applied to areas where such events result in very few contact points for scratching. This is because the lower cost does result in significant savings when dealing with larger quantities.

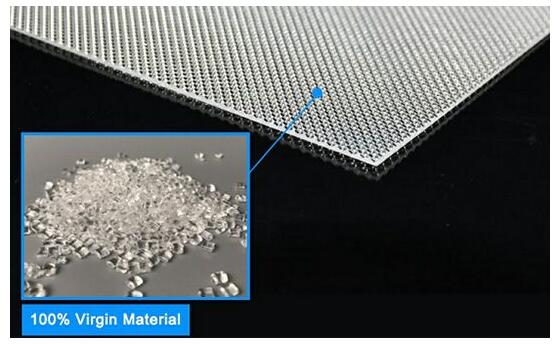

On the other hand, cell cast acrylic is more durable and has a harder surface due to the casting process. The process of cell casting is such that it is formed in a closed area. This reduces the chances of impurities entering the material. As a result, the final product looks clearer when it is made. Plexiglas is also a cell-cast acrylic. Acrylic is "softer" than "Plexiglas", but more forgiving under pressure. It can withstand higher pressures before breaking.

The most common problem with acrylic and plexiglass is the many names used in the plastics industry. Acrylic is the primary name, indicating the type of polymer used in its manufacture. Plexiglas is basically just a trade or brand name, and it is called plexiglass. So if you go to the store and ask for acrylic, you will get what is in stock in the store. Since "acrylic" is the main product name for the product, it is best to ask for "extruded acrylic" or "unit cast acrylic". Make sure you get the right product by knowing the different types of acrylic and understanding the differences between them.

The service life of acrylic-based plastics is a maximum of 7 to 10 years. This is usually the limited warranty for acrylic products marketed, but this limited warranty only covers fading and discoloration. Keep in mind that this does not mean that the material will last the full 10 years, as there are factors involved that can accelerate fading and discoloration. For example, if you live in an area with a high salt content in the air (wet or near a beach), the acrylic material may start to show signs of decay sooner. The same is true for acrylic panels that come in contact with alcohol or ammonia, which can also show signs of fading and discoloration more quickly. So, in short, the harder the surface, the longer the life you will get from your acrylic product.

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: