-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Anti Glaring Diffuser Sheet for UGR< 19 (Jk-PCLZB)

Unified Glaring Rating<19

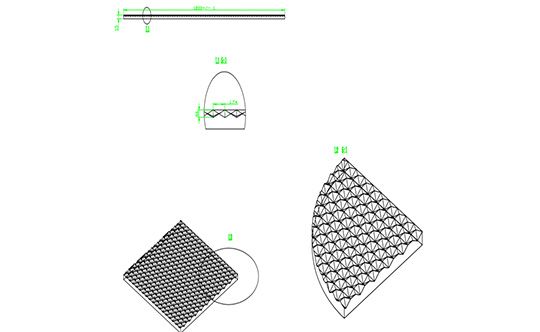

Pattern: Concave hexagon, cone bottom

Material: PC

Thickness: 1.2mm/1.5mm/2.0/3.0mm (can be customized)

Standard Size: 1200*1200mm (Can be customized)

Easy to fabrication

Enviroment Friendly

DESCRIPTION

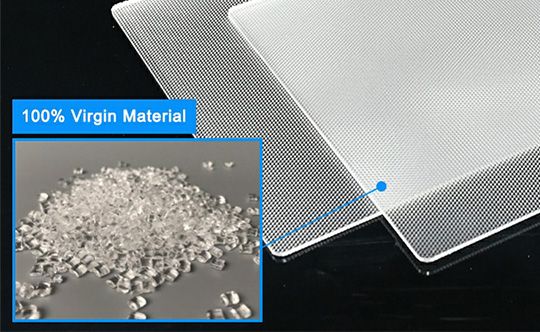

Excellent selection of 100% virgin material

On equal conditions, the light transmittance is obvious higher than traditional matte or orange peel texture diffusion sheet, at the same time effectively suppress the glare value

Scientific designed structure

Polycarbonate Anti-Glaring diffuser with Concave hexagon, cone bottom, takes on homogeneous look due to unidirectional structure;

Homogeneous glare reduction

Ther scientific designed structure, well defined lamp direction with average beam angle 85 degree, assist to improve the light efficiency and reasonable glare suppression; Homogeneous glare reduction in all C-levels, excellent for workstations required lighting application UGR<19, for example LED Panel light;

Material Character

| Item | Test Method | Unit | Value |

| Transmission rate | Transmissometer | % | 82% |

| Haze | Transmissometer | % | 90% |

| Water adsorption, 24 hours | ISO 62 | mg | 10 |

| Water adsorption, Saturation 23 ℃ | ISO 62 | % | 0.35 |

| Distortion temperature 1.8 MPa | JG/T 116-200X | ℃ | 130 |

| Vicat softening temperature B/120 | JG/T 116-200X | ℃ | 160 |

| Linear expansivity (23-80 ℃) | ISO 11359-2 | 1/℃ | 7.0E-05 |

| Thermal conductivity | ISO 8302 | W/m℃ | 0.2 |

| Oxygen Index | ISO 4589 | % | 25 |

| Flame retardant grade | UL 94-1996 | _ | V2/V0 |

Application

The application is different depend on the edge -lit usage or back-lit usage, for example if it's side-lit usage, there will be four layer structure, from the top to bottom will be UGR diffuser sheet, the diffuser film and LGP and reflective film, it can be illustrated that the UGR diffuser positioned in outer layer with the texture face towards the observer; The diffusion film located in the middle layer with the micro structure facing towards the LGP; the LGP be placed between the diffusion film and the reflective film, and with the dot side facing towards the diffusion film, the smooth side towards the reflective film.

If it's back-lit usage, there will be two layer, from the top to bottom will first be UGR diffuser sheet, then the normal diffuser sheet, and the structure will be the UGR diffuser positioned in outer layer with the texture face towards the observer; the diffuser sheet located in the bottom layer which more closer to the LED source

Polycarbonate Light Diffuser is a light diffuser material that comes in thicknesses ranging from 0.5mm to 6mm. LED lights, DIY lights, office lamps, kitchen lights, and fluorescent lights all have polycarbonate light diffusers as covers.

Need diffusers for a custom-made LED lighting rig? Replace the diffusers on your current LED lights? Choose us! Then you will get quality polycarbonate diffusion sheet, and 24h responce to your question of polycarbonate diffusion sheet!

OUR PROJECTS

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: