-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Light diffusers scatter collimated light from light sources to transmit soft and sober light. While the advent of LEDs has brought outstanding energy efficiency and excellent light control, point sources in LED chip boards present a challenge to general lighting in the form of glare. As a result, LED luminaires use specially designed covers that are optimized to provide light diffusion characteristics. In addition, these covers act as shields for the light source. While most LED light diffusers serve the same purpose, they are made of different key materials. And, this is where their quality comes into play.

Excellent Optic Diffusion Performance & Efficiency

The lighting industry has long relied on clear plastics such as glass and acrylics for optical design for functional and aesthetic purposes. However, with the advent of LED lighting technology, the need for a higher degree of light diffusion has required the development of suitable plastic solutions that can do a better job.

The most common diffusers on the market are made of PMMA - poly (methyl methacrylate), PS - polystyrene, PC - polycarbonate and PP - polypropylene. Lamp manufacturers prioritize the performance of these materials to make the best decisions.

Emphasis

● It has good optical properties.

● It adequately resists abrasion caused by surface scrubbing during cleaning.

● It has good chemical stability and thermal stability.

● It has high resistance to radiation.

● It resists moisture absorption, making it ideal for humid environments.

Disadvantages

● It has a low impact strength.

● It has low weather resistance. Prolonged exposure to outdoor environments can cause PS diffusers to turn yellow and become slightly brittle.

● It has very poor heat resistance. ps has a deflection temperature of 70-90°F, which is ideal for environments below 70°F.

In summary, PS has many shortcomings, but the advantage of using it in light guide panels for LED panel lights lies in its low cost. LED panel lights are generally used in indoor environments where the operating temperature is about 20-60°F, thus limiting its climatic impact. In addition, its low cost and good light transmission of 88% (lower than acrylic diffusers) make it an ideal diffuser for indoor lights.

PMMA/acrylic light guide

Emphasis

● It has high heat resistance and strong resistance to UV light, making them yellow-proof.

● With its 92% light transmission, it allows more light to pass through while requiring less power, resulting in higher lumens per watt for the luminaires that use it.

● Given that lamps with PMMA diffusers use less power to achieve higher efficacy, the LED chip is not overworked.

Disadvantages

● It is less impact resistant than PC, but much more resistant than PS diffusers.

● PMMA is a slightly more expensive material compared to PS, which pushes up the cost of the fixture.

Overall, PMMA / Acrylic diffusers offer excellent performance. Using PMMA as a light guide material in a flat ceiling light means a quality trouble-free fixture. Its high cost is balanced by its durability and efficacy.

LED tube light showing its PC diffuser

Emphasis on

● It has a high impact strength.

● It has a high heat deflection temperature.

● It is resistant to weathering.

Disadvantages

● It has a relatively low light transmission compared to PMMA light diffusers.

● It is an expensive material compared to PS, but the price is similar to PMMA.

In conclusion, in terms of durability and stability, PC diffuser is one of the best polymers to trust because of its high fire rating and good safety certification.

Chandelier with PP diffuser cover

Emphasis

● Compared to PMMA, PC and PS, it is much cheaper.

● Its soft shape allows it to be molded into complex patterns.

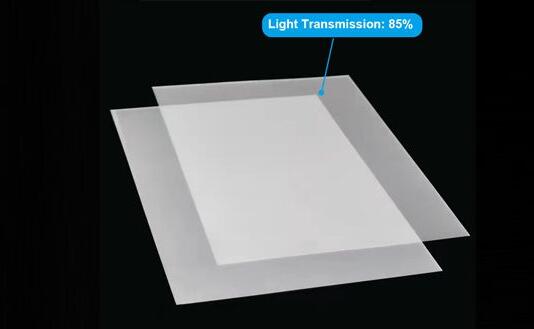

● It has a light transmission rate of about 85-90%.

● It does not require a coating on its surface, so it is easier to produce.

● It has good fatigue resistance and impact strength.

● It has good resistance to electricity, so it is a good electrical insulator.

● It is easier to repair from damage.

Disadvantages

● It is susceptible to UV degradation. Prolonged exposure in outdoor environment will cause PP diffuser to turn yellow.

● It is highly flammable.

All in all, PP light diffusers are less weather resistant and more suitable for indoor lights. Given its low cost and PC-like optical properties, it is an ideal replacement for PS diffusers.

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: