-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

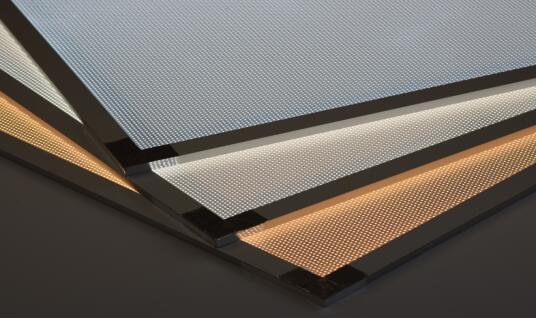

The light guide plate is made of optical grade acrylic/PC sheet, and then the light guide dots are printed on the bottom side of the optical grade acrylic sheet with UV screen printing technology using high-tech materials with high reflectivity and no light absorption. The use of an optical grade acrylic sheet to absorb the light from the lamp to stay on the surface of the optical grade acrylic sheet, when the light is shot to each guide point, the reflected light will spread to all angles, and then destroy the reflection conditions by the front of the guide plate. Through a variety of sparse, varying sizes of light guide points, the light guide plate can be made uniform light. The use of a reflective sheet is to reflect the light exposure on the bottom side back to the light guide plate, used to improve the efficiency of the use of light; the same area luminous brightness, high luminous efficiency, and low power consumption. Single-sided microstructure array light guide plate generally adopts the production process of extrusion molding.

The main function of the light guide plate is to direct the incident light from the backlight source to the LCD, to show the brightness of the backlight source and the display, and at the same time have the requirement of transmittance brightness and transmittance uniformity. Light is emitted from the backlight source, propagated inside the light guide, and refraction, reflection, and total reflection occur on the dot surface, part of the light is absorbed by the light guide, and the remaining light passes through the light guide and is incident to the liquid crystal material, through the control circuit to realize the liquid crystal display.

1. It can be cut into the required size at will, and can also be spliced and used, with simple technology and easy production.

2. high light conversion rate (more than 30% higher than the traditional board), uniform light, long life indoor can be used for more than 8 years, safe and environmentally friendly, durable and reliable indoor and outdoor can be applied.

3. the same area luminous brightness, high luminous efficiency, and low power consumption.

4. can be made into shaped, such as round, ellipse, arc, triangle, etc.

5. the same brightness, can use the teaching thin products, saving costs.

6. can use any light source, line light source to do the conversion of the surface light source, light sources including LEDCCFL (cold cathode lamp tube), fluorescent tubes, etc.

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: