-

Mob.:

+86 135 9088 4785

+86 135 9088 4785

Item No: JK-JYB

Surface Finish: hard coated

Acrylic Type: Extruded

Light Transmission:90%

Thickness:0.4、0.5、0.65、0.8.....2.0、3.0、5.0.....10.0mm(Can be tailor base on customer requirement)

Sheet Size:1250*1680mm (Standard)

DESCRIPTION

Excellent optical clarity and high impact strength

Abrasion resistant acrylic sheets are extruded sheet which offers excellent optical clarity and high impact strength with abrasion and chemical resistant properties. It is produced by applying a very hard, polysilicate coating to an optical acrylic substrate. It is available with coating on one side or two sides. While two-side coated sheet provides maximum protection, one-side coated sheet offers economical advantages for applications where only one side of the sheet is exposed. In addition, the un-coated side is ideal for silk screening.

One side & two side

Abrasion resistant acrylic sheets that one side coated is a great glass replacement for flat panel monitors, signs and LCD screens, and framing. Two side coated is suitable for interior and exterior break resistant windows and such so on.

Key Features:

A. offering excellent resistance against abrasion, scratches, chemicals and weather degradation.

B. Perfect material for surface protections, glazing, guard screens, displays and more.

C. Easily maintained with soap and warm water –no harsh chemicals needed

D Supplied with protective film on both sides.

E. Suitable for the fabrication of electroplating, hard coating and Screen printing .

NOTE:

ABRASION RESISTANT ACRYLIC SHEET IS NOT RECOMMENDED FOR HEAT BENDING.

Since The AR Coating Is Chemically Resistant, It Cannot Be Glued With Acrylic Cement. Glue Only Uncoated Sides And Edges.

Testing Method:

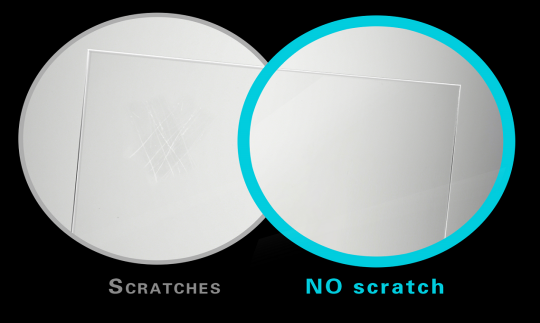

The excellent scratch resistance can be confirmed by the pencil hardness test.

This test involves a pencil being clamped into a device at a 45-degree angle to the surface to be tested, and then being slid across the surface of the test sample. The first pencil hardness (starting with the highest hardness) whose tip does not leave a noticeable scratch is considered the characteristic physical variable. For comparison, conventional acrylic sheet has a pencil hardness rating of HB, while abrasion resistant acrylic sheets has a 5H hardness rating, which is six degrees higher.

Characteristics

1)Material characteristics

| Properties | Test method | Test condition | Result | |

| Density | ASTM D792-08 | 23±0.5℃ | 1.19g/cm3 | |

| Water absorption | ASTM D570-98 | 50±3℃,24h | 0.27% | |

| Light luminoustransmission | ASTM D1003-07 | Specimen thickness:3.0mm | 90.0% | |

| Haze | <0.3% | |||

| Heat distortion temp | ASTM D648-07 | Width:3.00mm,120℃/hLoad:1.82MPa | 88.4℃ | |

| Vicat softeningtemperature | ASTM D1525-09 | Thickness:3.0mm,120℃/hLoad:50N | 104.0℃ | |

| Mold shrinkage | ASTM D955-08 | 23±2℃,50±5%RH,48h | Parallel to flow | 0.37% |

| Perpendicular to flow | 0.31% | |||

| Tensile strength | ASTM D638-10 | Thickness:3.0mm,5mm/min | 61.8MPa | |

| Elongation at break | 3.0% | |||

| Tensile modulus | 3270 MPa | |||

| Flexural strength | ASTM D790-10 | 3.0mm,1.3mm/min48mm | 107 Mpa | |

| Flexural modulus | 3310 MPa | |||

| IZODnotched lmpact strength | ASTM D256-10 | Width:3.0mm 1J | 15J/m | |

| (HRR)Rockwell hardness(HRR) | Hardness Pencil Tester | ASTM D3363 | 4H | |

| Adhesion | Boiling tester | 30mins in Boiling water | 5B | |

| Wear resistance | Taber Wear resistance tester | 1000g/cm2,stroke:3.3cm speed:40 cycles/min 200 cycles | No scratch | |

| Waterproof | Boiling tester | Soaking in water 24h | No change | |

2)Dimension

| Dimension(L×W×T) | ||

| Length | Width | Thickness |

| 1250mm | 1680mm | 0.5~10.0mm |

| Surface: One Side Coated / Two Sides Coated | ||

| Note: According to customer demand for different mold, build the required size | ||

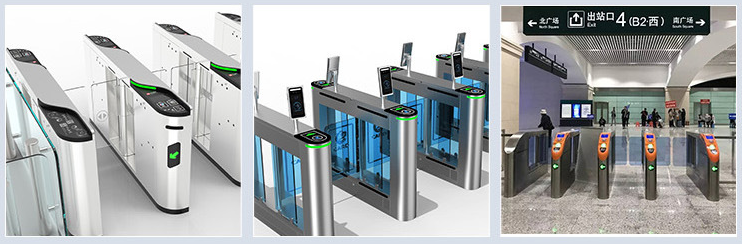

Applications:

The hard coating provides acrylic sheets with a surface that has 40 times the abrasion resistance of uncoated acrylic, making it an attractive material for applications that require the safety and frequent public contact and involved heavy use, such as displays, exhibits and fixtures, abrasion resistant sheet will help maintain a “like-new” premium appearance much longer.

Can be widely used in:

A. Furniture, exhibition booth construction and shopfitting

B. Large-scale wall cladding

C. Marker boards

D. Glazing

E. Fittings and display case construction

F. Displays

G. Aircraft industry

H. Industrial glazing

I. Signage

Copyright ©Kunxin New Material Technology Co., Ltd. All Rights Reserved | Sitemap | Technical Support: